EPISODE 623 “WHY ONTARIO BARNS HAD WHEELS?” ROBERT ROOT ANSWERSalan skeochjuly 2022Most Ontario barns also had wheels high up on the high beams. Why ?This was time when barns also used teams of horses , lots of long ropes, pulleys attachedto the floor and lots of two and three pronged forks. About now, end of July, those wheels were movingas were the horses, ropes and pulleys….and the pitch forks.. Why?

This is BoB Root, who I call “Rooter” for no particular reason other than friendship. Our life paths

have crossed many times. He has answered my questions about the rack lifters in detail.

And even sent a note about another method of getting loose cut hay into hay mows on

either side of the threshing floor of Ontario barns. Both methods were a lot of work. But

hay had to be stored as winter feed.

MY MEMORY IS FAULTY. I THINK UNCLE FRANK USED THE HAY CAR METHOD

DESCRIBED BY BOB ROOT RATHER THAN THE HAY RACK METHOD. I HOPE TED

FREEMAN WILL CORECT ME. S BOTH METODS ARE DESCRIBED BY BOB.

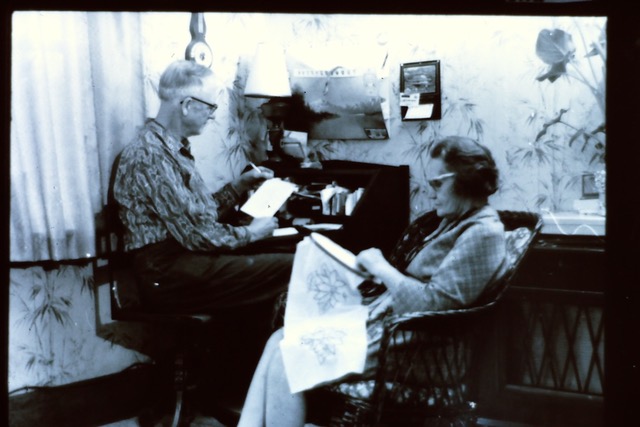

Hi Alan,Those wheels were used as rack lifters. The wagon load of loose hay or straw would be pulled up by the team of horsesso that the load would be positioned under the wheel assemblies.Ropes would be attached to the wagon rack and the axles of the wheel assembly.Horses would then pull on the ropes around the wheels and the wagon rack would be lifted off the wagon frame andraised to the level of the haymow where the farmer could fork the load off of the wagon rack and into the haymow.The unloaded rack would then be lowered back onto the wagon frame where it could return to the field for another load.This was all a lot of work in the days before hay balers and elevators were invented.MY UNCLE FRANK FREEMAN AND HIS WIFE LUCINDA(Cousin Ted Freeman had grown up when this picture was taken)Of all my farm relatives, Uncle Frank and Aunt Lucinda Freeman worked the hardest and got the leastreward for their labour That is my opinion. They would never say this. I am not sure if cousinTed would agree. Their farm was in a nest of hills that drained into a large pond that was deadcentre. Tough land. Lots of stones and lots of danger. I spent a lot of time with them, morethan with any of our legions of Skeoch farms around Fergus. I never appreciated how hard theyhad to work to make a living until they were gone.This picture of them at rest is inappropriate because they never hadmuch time for rest since they had to squease an income from the pilesof glacial till left for them 10,000 years ago when the Laurentian ice sheetmelted.Bob Root has explained the rack lifting system.Hi Alan,Those wheels were used as rack lifters. The wagon load of loose hay or straw would be pulled up by the team of horsesso that the load would be positioned under the wheel assemblies.Ropes would be attached to the wagon rack and the axles of the wheel assembly.Horses would then pull on the ropes around the wheels and the wagon rack would be lifted off the wagon frame andraised to the level of the haymow where the farmer could fork the load off of the wagon rack and into the haymow.The unloaded rack would then be lowered back onto the wagon frame where it could return to the field for another load.This was all a lot of work in the days before hay balers and elevators were invented.

This is what a hay wagon would look like when driven into the barn…only this

is a load of sheaves of wheat being fed into a threshing machine by cousin Eleanor and her

husband James Calder other Bellwood farm.

Robert Root

“On our farm we didn’t use this method but the Awrey farm across the road from us did.”

“On our farm we used a hayfork system. The loaded wagon was pulled up onto the driving floor and the large hayfork was plunged into the load of hay. Horses with a rope attached would then walk out the gangway pulling the rope behind them and this would lift the hayfork loaded with a large bundle of hay up to the roof level where a 4 wheeled trolley ran along a track and it could carry the hayfork forward or backwards and also sideways into various mows. At the desired location the jaws of the fork would be opened and the bundle of hay or straw would be released and fall down into the mow. By the time I was a kid the horses were replaced by a tractor which pulled the long rope up and down the gangway. I remember one day that my cousin Ken and I were sitting in the sand playing at the base of the gangway and the rear tire of the tractor ran over Ken’s outstretched legs as it pulled the rope to lift the hayfork.

This whole process was very dusty and so when balers became available we quit the hayfork business but the hayfork track always remained hanging from the inside peak of the barn roof.”

“Rooter….how much hay would 1cow need for winter…or a horse…miscalculation = starvation…I wonder how farmers made this calculation””“Trial and error, Alan, If it looked like the farm was going to run out of hay then a couple of animals would have to be butchered.”