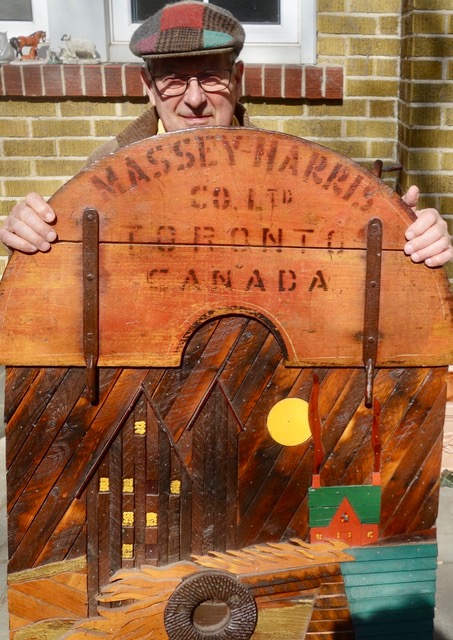

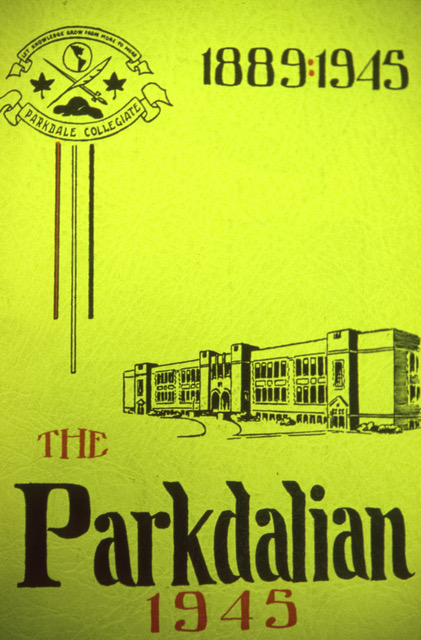

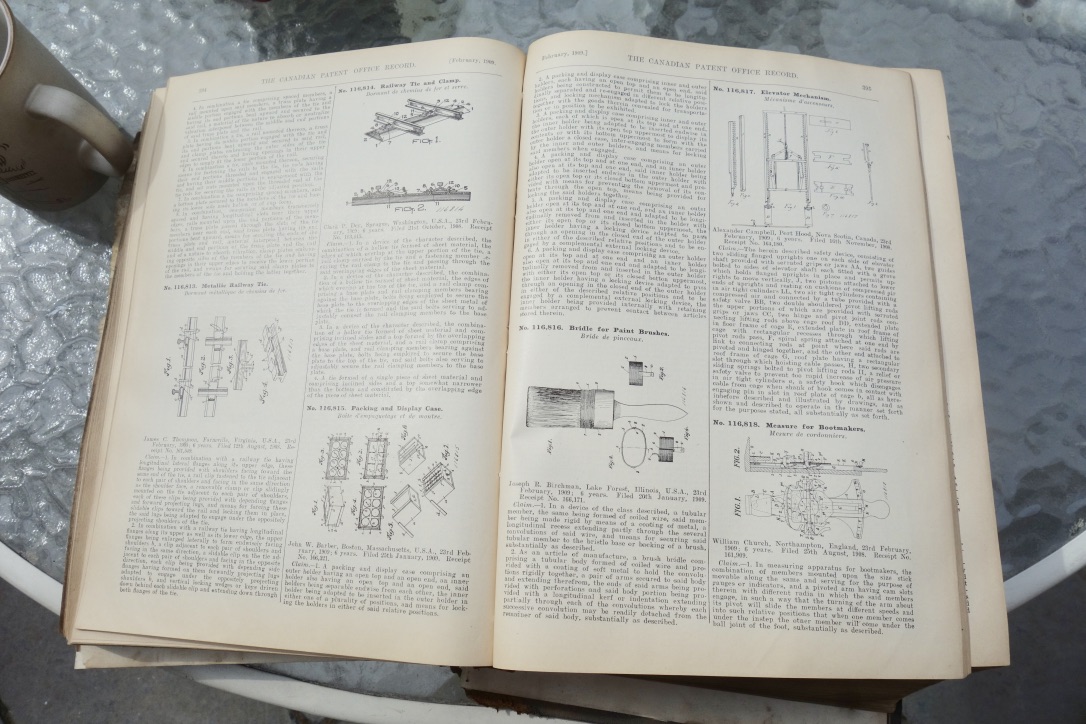

EPISODE 280 DEMOLITION OF MASSEY FERGUSON: RESCUING LINE SHAFT PULLEYS

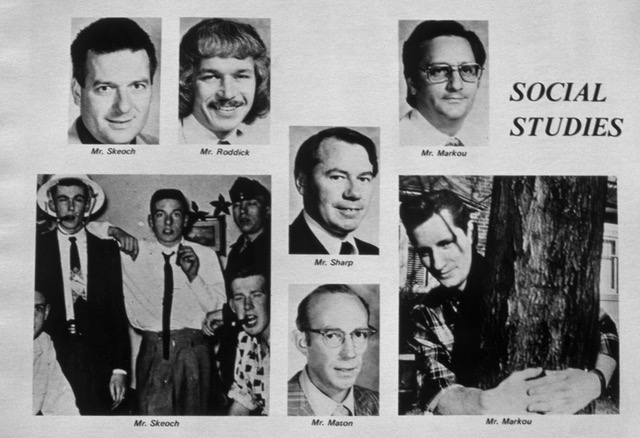

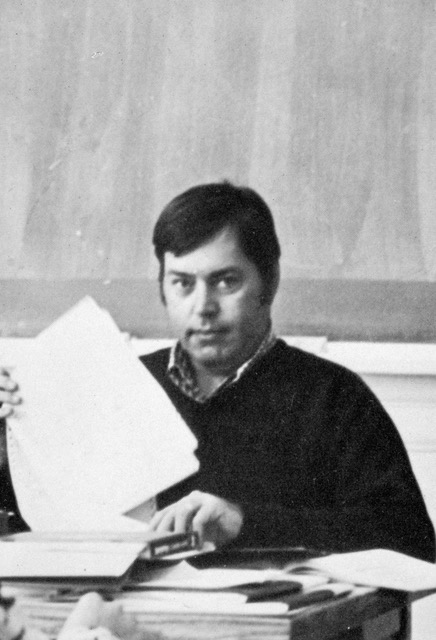

alan skeoch

March 2021

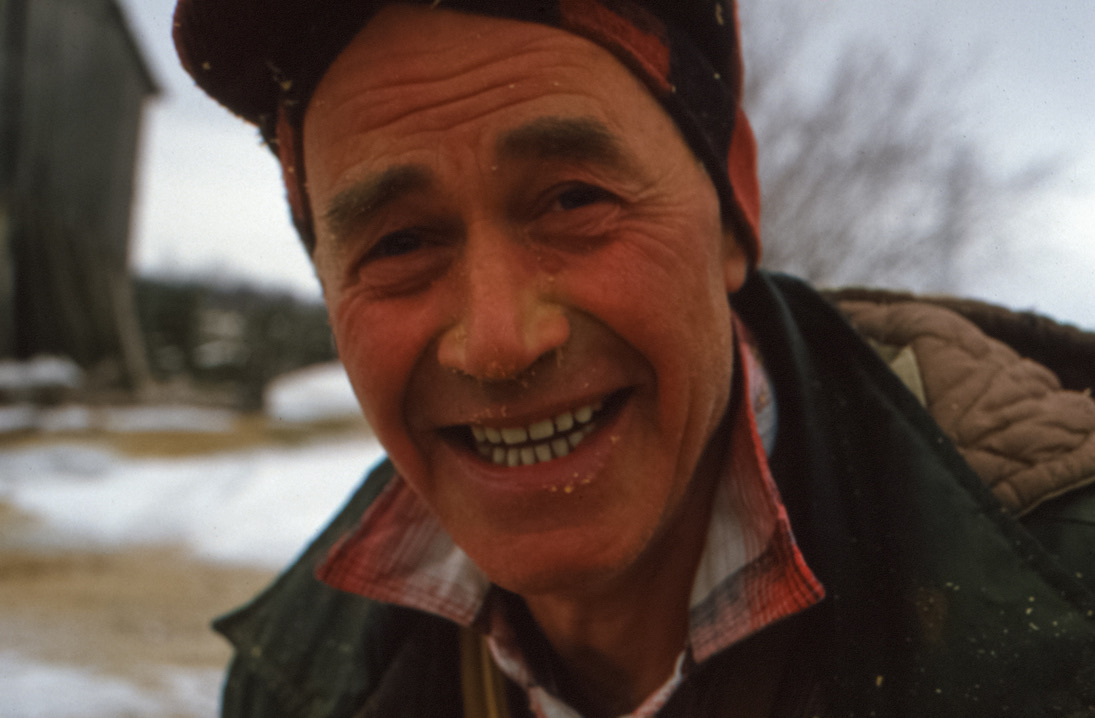

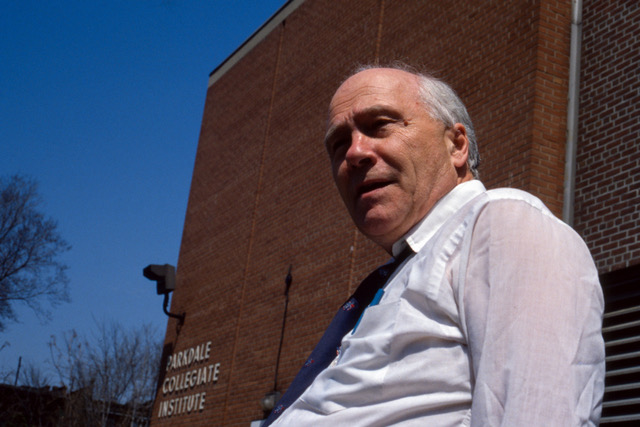

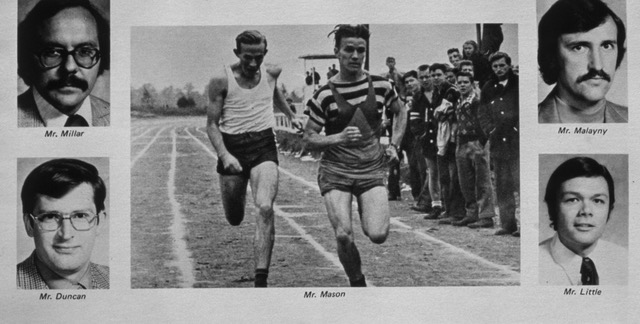

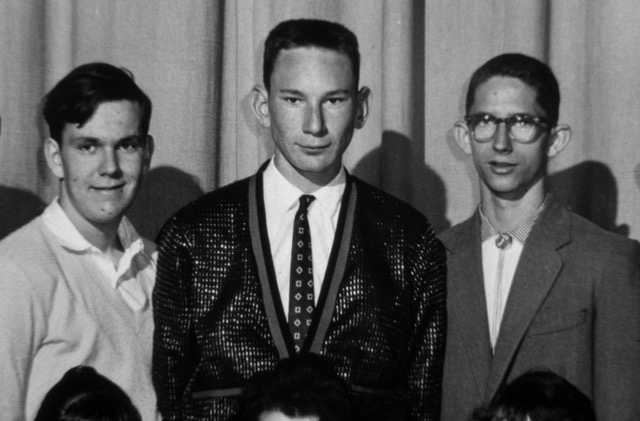

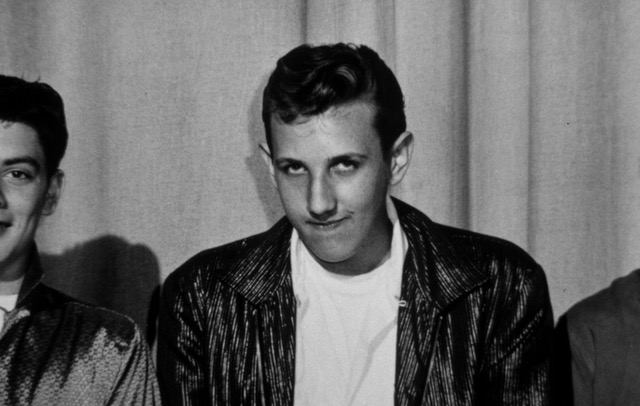

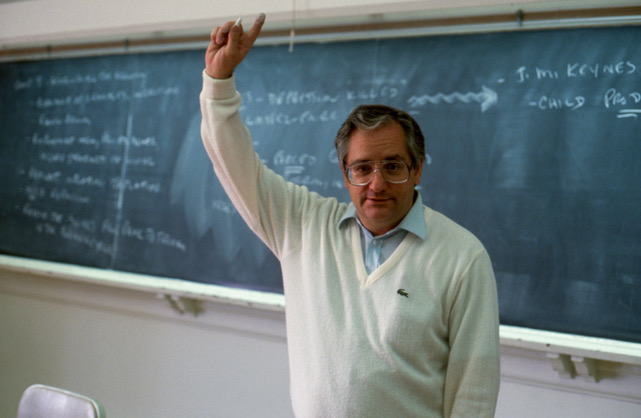

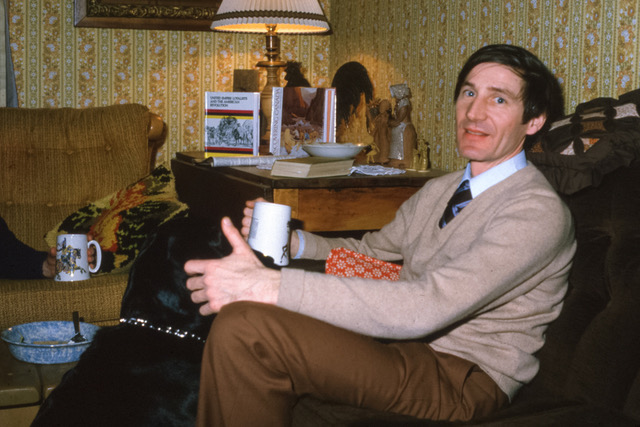

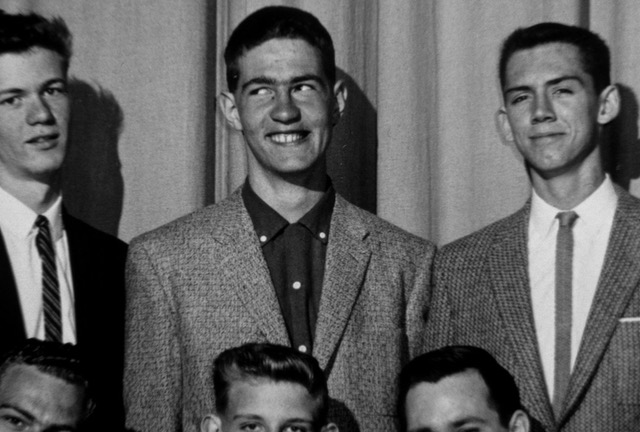

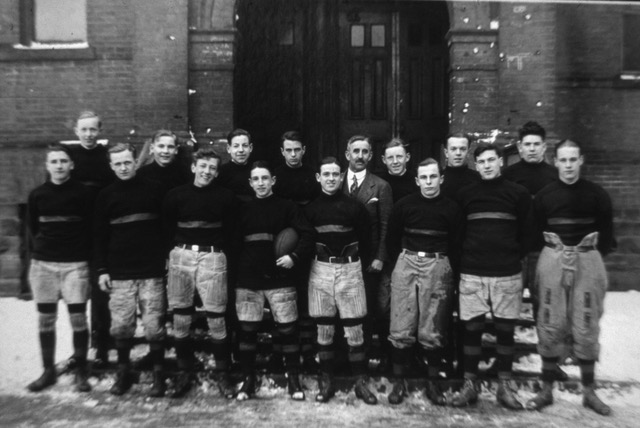

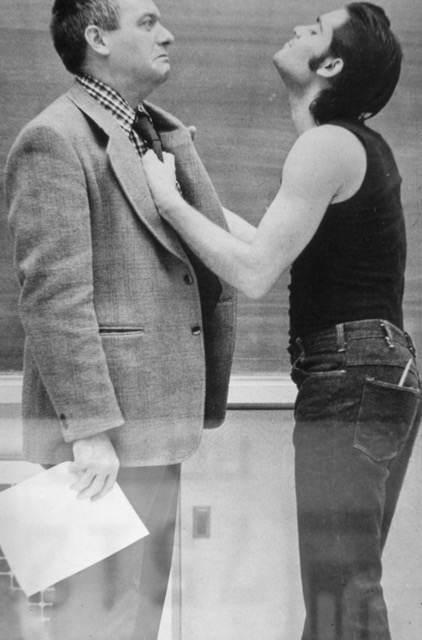

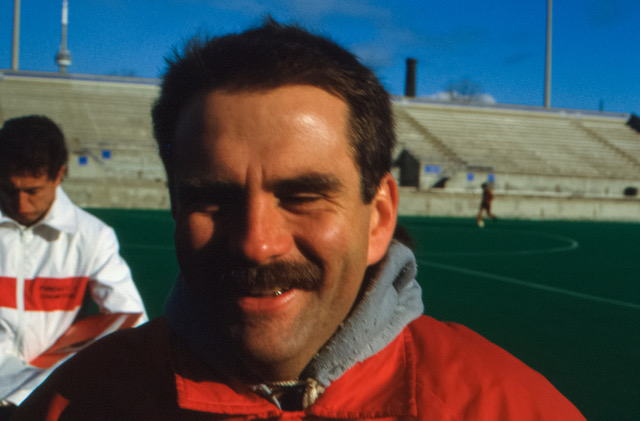

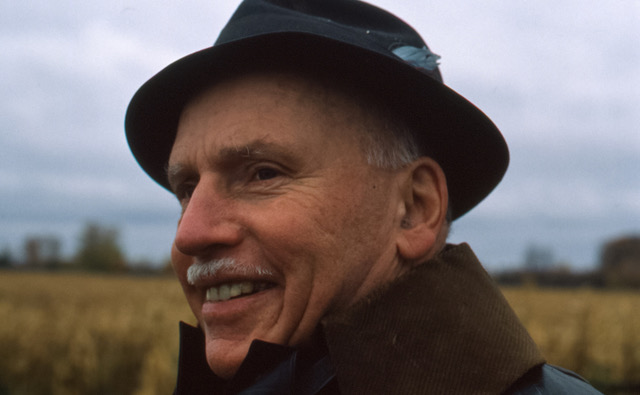

ARNOLD ‘RED’ SKEOCH…TIRE BUILDER

DAD MADE TIRES LIKE THESE IN 1920…LATER HE MADE THE BIG TRUCK AND TRACTOR TIRES. PROUD OF IT. SKILLED TRADE.

Why was I so interested in those line shafts hat were being ripped from the ceiling of the Massey factories in 1980?

A legitimate question. I ask myself the same question once

in a while. Why would anyone want ro spend

days and weeks high on ladders unbolting ancient wooden laminated pulleys that would never be used again.

The answer? My dad was a factory worker…a tire builder. He spent much of his working life beside the swift moving belts

that ran from line shafts in factories across the industrialized world. He did not make farm machines. He made rubber tires.

Rubber tires made for the passenger cars of the 1920’s. He was a very tough

man…a proud tire builder…member of a skilled trade.

Natural rubber was needed big time. It still is needed…both an aural and vulcanized rubber. From the Amazon rain forest came this peculiar gum upon which great swaths

of human society would ride. Rubber tires, initially solid rubber then the pneumatic tires.. The story of rubber

is too large for this sidebar….suffice it to say that rubber tires in the 1920’s had replaced Iron and wooden wheels on farm machines

as well as trucks and automobiles. Today rubber is taken for granted…not talked about but it is worth

remembering that those huge four engined jet passenger planes could not take off or land without rubber…natural rubber.

Dad never said much about his work when we were little kids. When asked, however, he did say

a few things about the line shafts on which all manufacturing depended.

“Were those line shafts dangerous, Dad?”

“Bloody right they were dangerous. Do you really want to know?”

Around 1919, After dad got back to Ontario from a winter on the prairies living and bedding

down 16 horses in a barn…no farm house, no people, jus 16 horses…after that experience…dad welcomed the switch from a rural to

an urban life. The motor industry was booming. Cars and trucks needed pneumatic rubber tires

so dad became a tire builder.

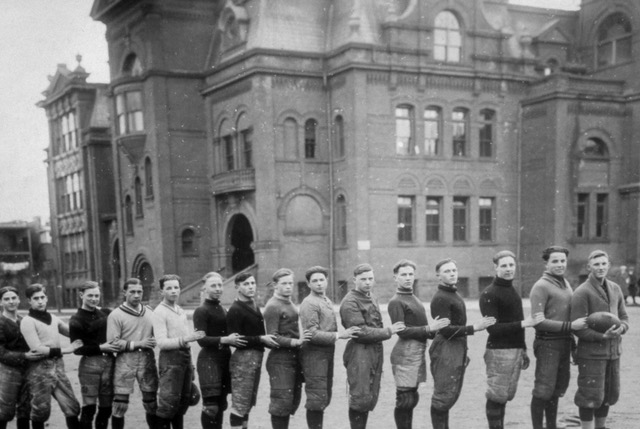

“What did those factories look like, dad”

“Our factory in Guelph was powered by belts running off a line shaft.”

“Line shaft?”

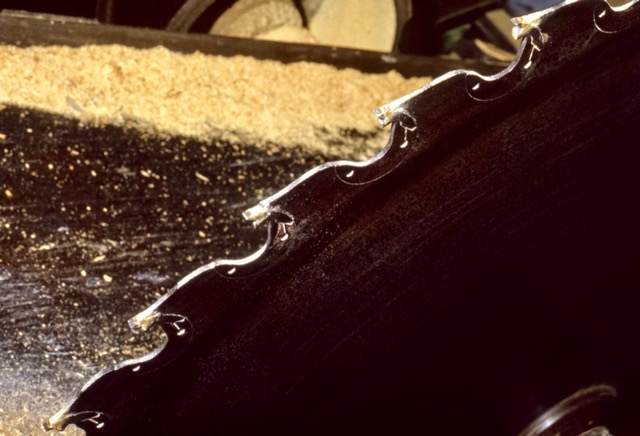

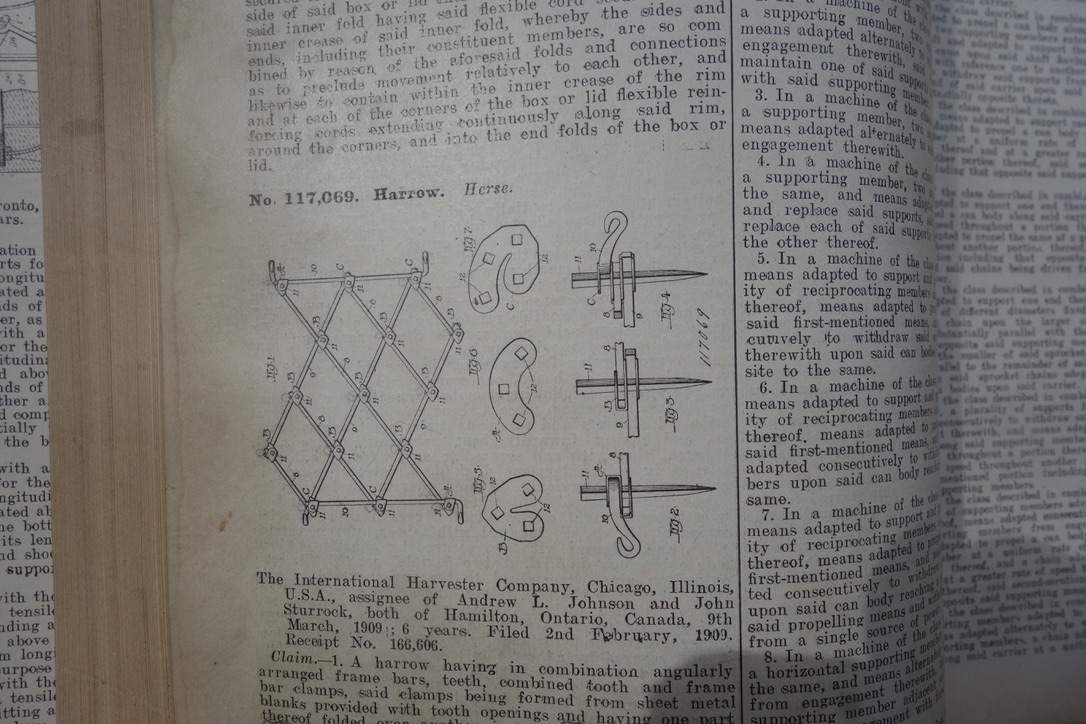

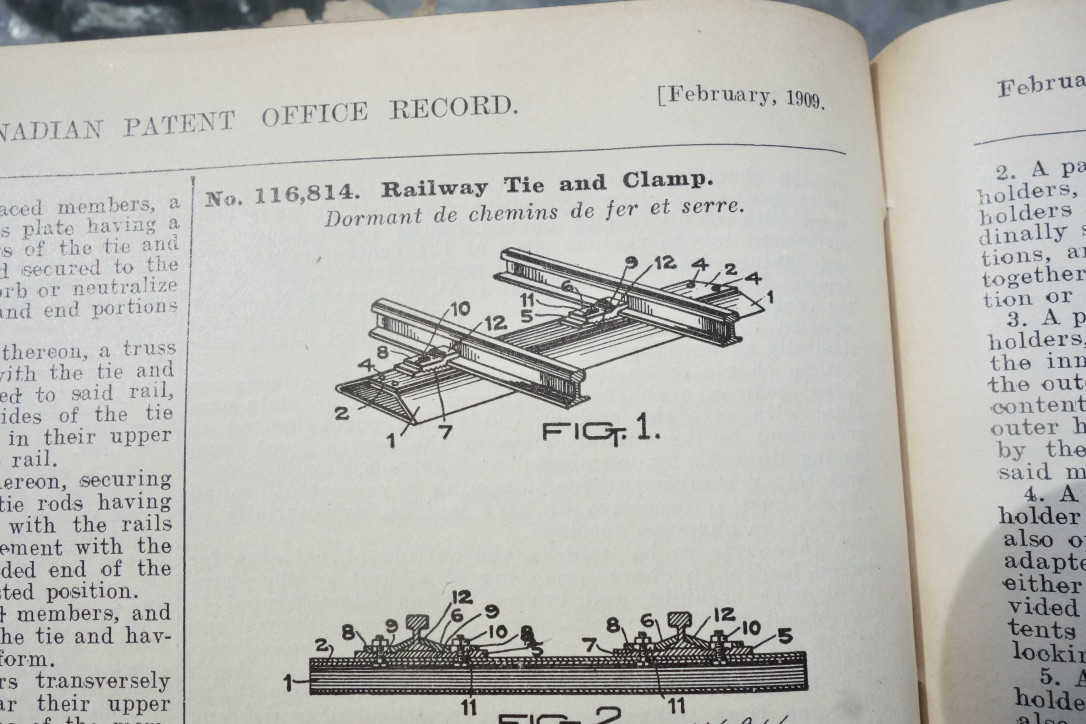

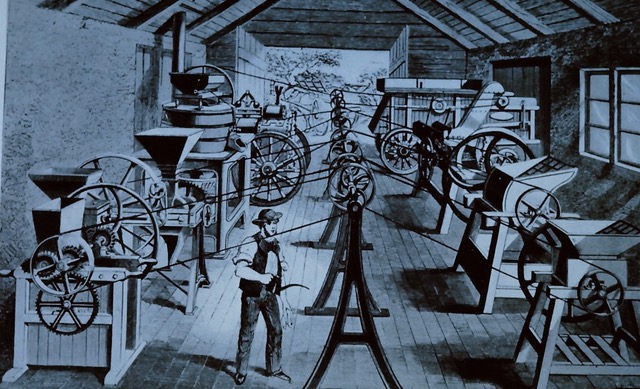

“A long piece of thick rounded steel rod with pulleys of various sizes bolted to the rod.”

…and the rod revolved via a belt looped around an electric motor…or a seam engine in early factories. Bloody dangerous.”

“Dangerous?”

“I saw a young man killed on a line shaft. It was not pretty.”

“In order to shut a machine down there were two choices. First

choice was to turn the motor off but then all machines would

shut down because the whole line shaft would not be moving.

Companies did not like that.”

“So, what was the second choice.”

“Just shut one machine down;””

“How?”

“There was usually an idling pulley right beside the drive pulley. If

the belt could be edged over to the idling pulley then just that machine

shut down. Often there was a lever that could gently move the big belt

from drive to idling. I am not sure why the guy decided to push the

belt by hand. No one knew why he did that. In an instant his arm slipped into the

drive pulley and his body was wrenched up and around the line shaft. By the

time the motor was shut down he was dead as a doornail with some body parts

detached.”

Now was that story true? Had my mind magnified the story? Never totally sure so I looked up lineshaft accidents

on the internet. Seems that many workers got their body parts severed on revolving

pulleys attached to line shafts. Do so yourself.

Dad did not stop there. He had a more chilling story about a new employee

at Dunlop Tires Corporation … I think the Whitby plant.

“Some guy took a short cut across the rubber rolling machine…he came

out the other side flat as a goddamn pancake.”

A much shorter story that may or may not be true. I believe it. The week dad retired

Eric and I asked if we could visit the factory. We wanted to see how dad spent his working life.

We got the royal treatment from the

executives and the foreman. Dad was busy making truck tire. Seemed a little odd for Eric and I to be escorted

around the White plant while our father was slapping heavy belts of rubber…vulcanized rubber.. onto a

spinning machine then carving the rubber into a tire. Dad was always in good shape physically

because tire building needed strong men.. He grinned at us as we passed his work station.

His clothing was spartan…a sleeveless T shirt and belted work pans. Nothing for the

spinning machine to grab. No jewelry.

If I remember correctly we also passed by the long

rubber rolling machine. We did not take that short cut that made pancakes our of

rubber workers. Dad did not want Eric or me to become tire builders. Why? Take a guess.

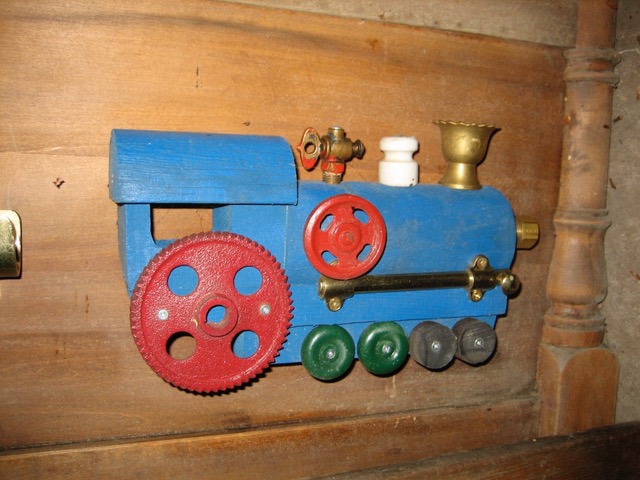

An artist’s sketch illustrating a line shaft powering many machines

A more complicated line shaft powering real wood working machines.

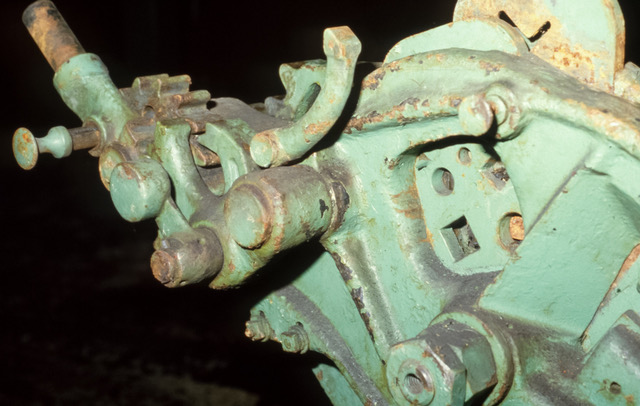

Some line shafts in the Massey Ferguson factory. Awaiting rescue. These I was able to reach using a step ladder. Shaky job but

I had no worries. Superman.

Now these beauties were another matter…they were 20 feet in the air. Impossible to reach. Well…not quite…!

IN the back of my mind were the stories dad mentioned so casually about those early line

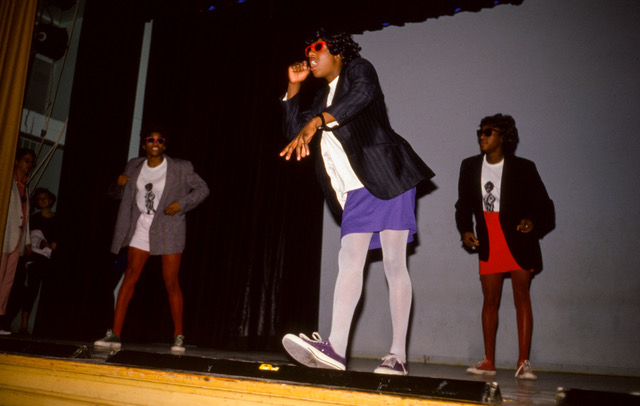

shafts. Wouldn’t these things be needed for horror moves?

Note the bolts. Once removed carefully the pulleys spill into two parts which I then revolted back together.

Most of the time I was absolutely alone in a building that had not been touched by the wrecking ball. The wrecking was going on

in other Massey buildings. Where I worked there was no one around. Some buildings I could even drive my

truck into for fast loading. Some of these pulleys were so big that even when bolts removed the two halves were a bit of a problem getting from

the ceiling to the floor and then into the back of my truck. Wouldn’t the big pulleys be grand show pieces for a movie. I felt elated by both

the challenge of recovery snd the prospect of a bit of profit.

You can get some idea of just how high the line shafts were in this factory room. So high up as to be invisible. Then I fount the gantry.

(Unsure if this is he right word…gantry)

Yet the real beauties (if a mineshaft pulley can be called a beauty)…yet those grand pulleys were way beyond reach. Twenty feet up. So I wrote them

off. Then by a quirk of fate I discovered an abandoned gantry on wheels…. A set of movable stirs with a small platform at the top…on

wheels the size of dinner plates. So for two or three visits to the factory i was high up in the air liberating some grand pulleys. They were oily and

dusty…messy job… have time to wash at school before class.

In the end I managed to get about 30 or 40 of these pulleys.

Guess how many have been used on movies sets between 1980 snd 2020? You got it. None. Not one goddamn pulley. There was joy in the getting.

That was good enough for me.

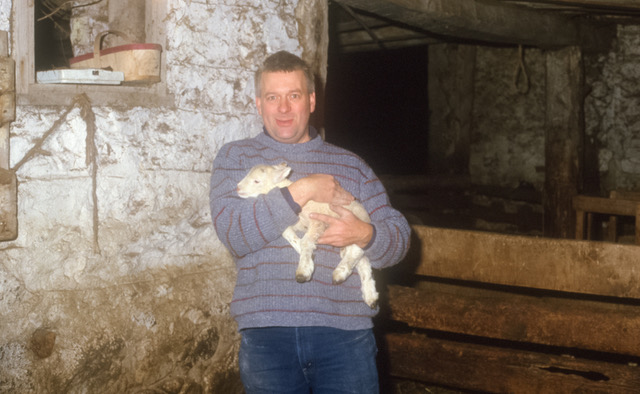

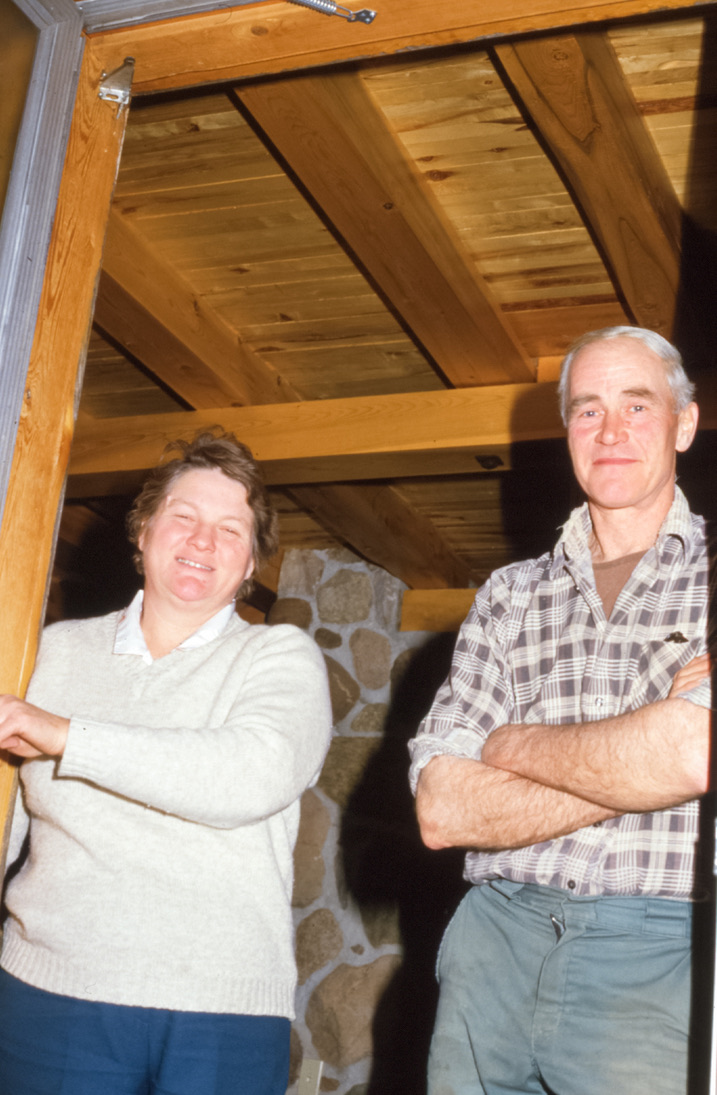

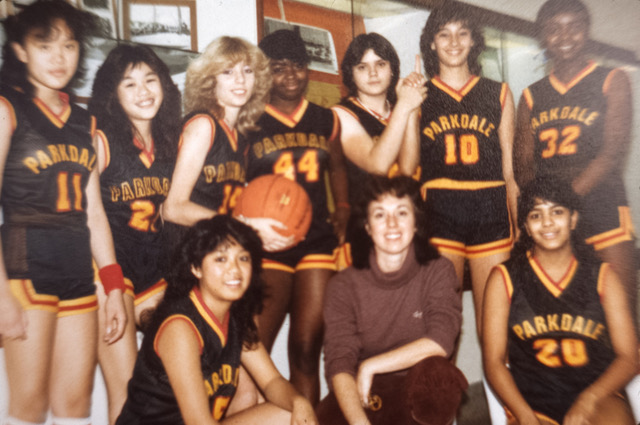

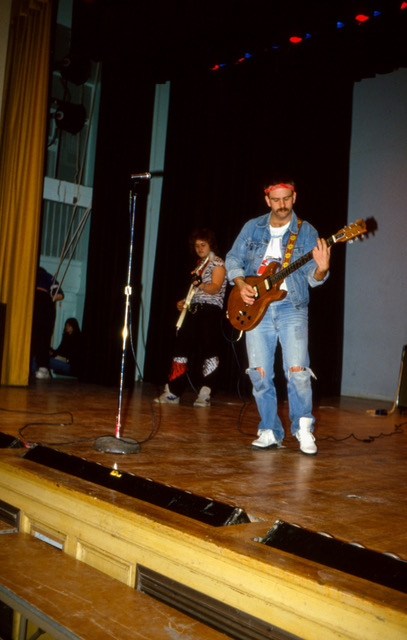

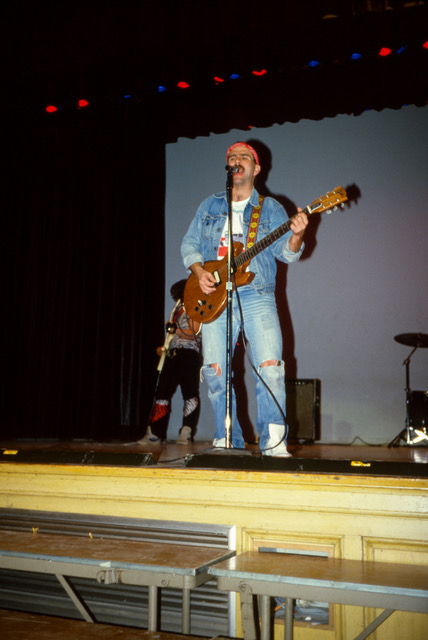

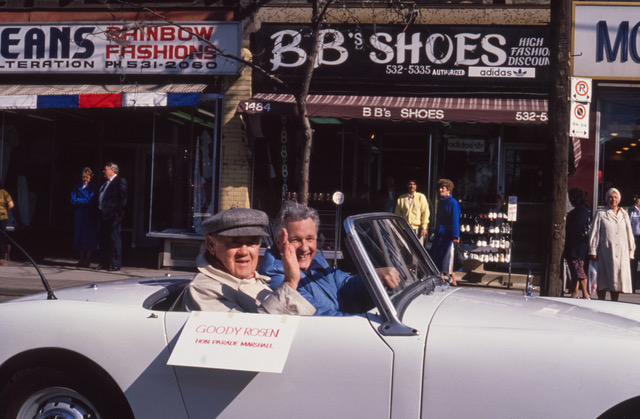

MAY I INTRODUCE YOU TO A RUBBER TIRE BUILDER” ARNOLD “RED” SKEOCH

DAD and his fellow retired rubber workers met annually at the Royal York Hotel.