EPISODE 177 THE MCCORMICK REAPER PROJECT

alan skeoch

Nov. 2020

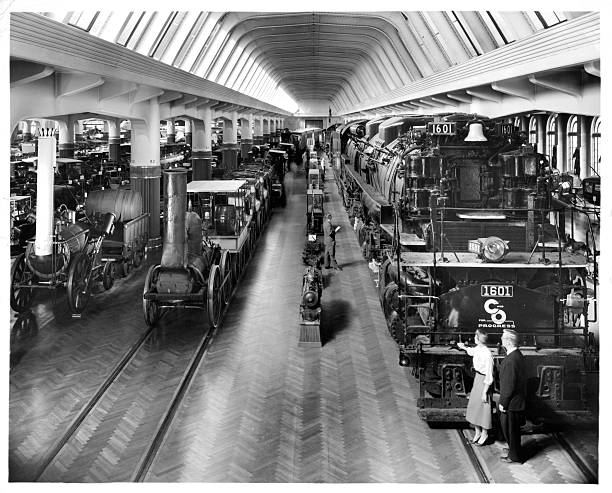

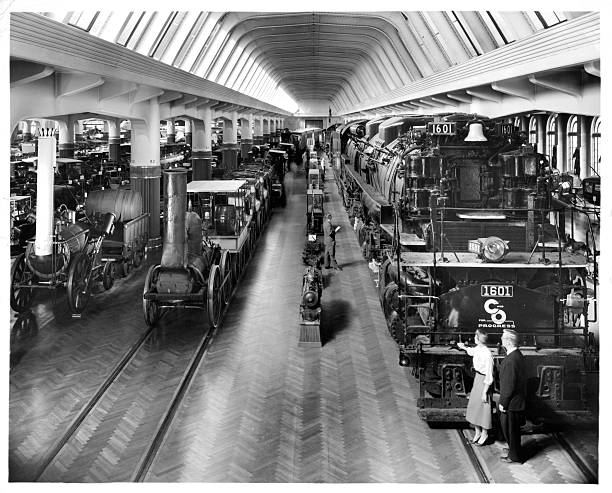

McCormick Reaper…scale model of the 1831 invention of Cyrus MCCormick as restored in our back yard and chicken coop around

1981…half a century after 100 scale models were built to celebrated the century of The McCormick Reaper.

THE ADVENTURE REBUILDING A MCCORMICK REAPER (CIRCA 1931, REPLICA 1931)

This McCormick Reaper may look primitive to readers when placed beside a picture of a modern

Combine Harvester. When the picture is placed beside the original model reaper built by Cyrus

McCormick in 1831 this picture looks quite sophisticated. Technology changes. And change continues

to happen.

THE CYRUS MCCORMICK REAPER PROJECT

“Alan, aren’t you getting yourself into this project a little too deeply? What do you know about repairing…rebuilding….historic

machines?”

“True. But I just could not let the opportunity slip by.”

“But you are dealing with big shots…an executive with the Mellon Bank of New York. Why didn’t you

tell him you were a high school teacher…a teacher of history?”

“I guess I found it easier to say yes than to say no.”

“Could be a deep hole you are stepping into.”

“I know…makes me a bit nervous.”

“How did they get your name?”

“I think Peter Cousins at the Dearborn Museum … near Detroit …must

have passed my name along. I had been doing all that research on machine

technology much of which was centred on the collection of Henry Ford.”

“What are you going to do now?”

“Well, first thing is to get the machine and bring it here.”

“Where will you put it” Sounds like a big machine.”

“I’m emptying the garage….the McCormick Reaper is about

the size of a car.”

“You have already converted part of the garage and the attached

old mink house into a chicken coop. Where will the chickens go?”

“Nowhere. They will keep the Reaper company…lots of room.”

“Alan, our home is not a farm.”

“Lucky we have this huge lot…lucky we live on the old Mississauga

reserve with non conforming property lines…lots of room.”

“is this legal?”

“Perish the thought.”

“Next step?”

“To get the reaper and bring it here.”

“How?”

“Gary Duncan has offered to help. His brother runs a truck rental agency

and has offered a five ton truck for Saturday. Gary and i will drive down

to Merlin.”

“Merlin?”

“Small farm outside Merlin where the current owner of the reaper keeps his

collection of things.”

(Note: Forgot his name at the moment but remember him so well)

“How will you load the reaper?”

“Easy…the five ton has an hydraulic ramp…piece of cake.”

WHEN the rental truck failed on Highway 401 , we tuned to our Ford Van and a little trailer as an alternative. Here is a picture with

a different load and one of ours sons, Kevin, tightening up the straps. The McCormick Reaper was loaded successfully

Unfortunately the ‘Piece of cake” was not that easy. The five ton truck

broke down on the 401 before we really got out of Toronto.

My van would have to be the back as Gary and I

headed for Merlin, a small town south west of Chatham. East of

Windsor…east of Detroit.

The cutter blades were designed differently from the BellReaper…more like a saw than garden shears.

“How can you carry the reaper in your truck?”

“We’ll put it in the trailer.”

“I thought the trailer was broken. Didn’t it come loose and

end up in a swamp near Fergus”

“That was months ago. Got it fixed.”

“Will the reaper fit onto a two wheeled homemade trailer?”

“Hope so.”

Gary and I managed to get to Merlin without trouble. The retired

farmer (whose name I must find again) met us at his small two

storey drive shed where he kept the reaper.

“Let me help get the reaper onto the trailer…two long planks should do it.”

“Really only need one plank…the McCormick Reaper has only one bull wheel.”

“Between the three of us we can get her on…winch attached to the truck

and one of us on each side so it does not tip. “

“Moving up a foot at a time. There. Done. Now we’ll lash

it down…”

I remember clearly speaking with the owner of the reaper but cannot

be sure how he got the machine. I think he said that the reaper had

been on display for a time and then put into some kind of storage shed

where it sat for decades.

One thought kept bothering me. “How could such a delicate machine

have survived for such a long time? No apparent invasion from powder

post beetle. Almost intact.”

I found out later that the reaper we strapped down on my trailer was not the

reaper everyone thought it was. It had not been built in 1831 by

Cyrus McCormick. This machine had been built a hundred years later in 1931 to celebrate

the McCormick invention. A replica. One hundred scale models had been built

by the International harvester Corporation to celebrate the original inventor.

That knowledge was a bit of a relief. I would not be fooling around with

a machine that was really historic. There might be a few others around

somewhere even though there was no evidence of such. If this had been

the original McCormick machine it should have gone directly to the Smithsonain

in Washington. One McCormick replica did exist in the Dearborn collection.

But perhaps the Dearborn Museum McCormick reaper was ancient. Now

safely on display. Protected. In no danger.

In short, I was more relieved that mine was a replica. More pleased than disappointed. I would not be restoring

the Mona Lisa.

“So what are you going to do with the money?”, I asked gently

“It will pay for my funeral.”

“I beg your pardon,” I really was not sure I heard him correctly.

“When I die, this money will bury me…cover any funeral expenses.

I won’t be a burden on my family that way.”

There was not much more we could say.

With that touching comment, Gary and I revved up my Ford van and

began our careful return to Mississauga. It was a long day but we got

the reaper home and rolled it into the garage (chicken coop) for the

restoration to begin.

All the immediately visible parts were evident but in the back of may mind

I wondered why we could roll it so easily. Must be an idling pulley or some arrangement

that kept it out of gear for moving around.

The next discovery really knocked me for a loop.

In this picture you can see the big but gear clearly…bevelled, sprocketed.

“Where is the bull gear?”

“Bull gear?”

“The main gear…the sprocketed bevelled gear that converts the forward motion of the horse

into power that drives the cutter bar. “

That discovery was made when we got the reaper to Mississauga. There was ‘no joy in mudville’ that day.

Sure enough the large cast iron bull gear was missing. Any other missing part might be replaced. The

absent bull gear was a devastating discovery. If I was a real mechanic I would have noticed. What could

i do? How could I get another bull gear. Even if I toured every scrap yard in North America it

was unlikely I would find another bull gear.

In shock, I sat on a stool beside the machine. Afraid to tell anyone. Fully aware that such a gear could

not be found. Nor could a bull gear be made. The pattern…the sand mould…had been dumped into

garbage back in 1931. Here i was half a century later telling a banker I could restore the reaper. Telling

him a big lie. I should have qualified my answer…should have said I would take a look at the job.

Instead i had agreed with him on a telephone call. Thankfully there was no formal contract. Maybe I could

weasel my way around the situation. That would make me look like a fool of course…which was nothing new.

“Alan, where could you find another bull gear?”

“The only place possible is the McCormick reaper on display at the Dearborn Museum.”

“Well?”

“Well, I could hardly go into the museum and remove the bull gear from a prize exhibit. That

would be like taking Mona Lisa’s smile. No one would let me do that. I am in trouble.”

“You could ask Mr. Cousins. Nothing ventured nothing gained.”

“OK…I’ll give it a try.”

Ring, Ring , Ring

“Peter, this is Alan Skeoch from Canada, I have a big favour to ask.”

“Yes.”

“Would the Ford Museum let me take the bull gear off the McCormick Reaper.

I am in a real box here as that bull gear is missing and the only way I can

see around the problem is to get your display model’s bull gear and then

get it duplicated somehow.”

Pause…long pause…”Yes, I suppose that could be done. Be careful, give me a

few days to get the clearance then come down here a take the gear away for a month or so.”

“Great, Peter, I will fly down on the week end.”

“Bring your own tools…I will get you a pass.”

So I was on my way. One step at a time. I really did not know what i would do with

the bull gear if I did manage to get it off the reaper. I would have to use it to make

a sand mould and then find some factory that would be able to pour molten iron

into the mould. But that would be the next step. First, I had to get the bull gear.

One step at a time, Alan.

“Marjorie, book me on a flight to Detroit … need one night in a hotel

near Dearborn. You were right. Peter Cousins has given me a permit to

borrow the McCormick bull gear.”

“Do you know how to get it off the machine?”

“Nope. But I will figure it out.”

“Alan, this project is costing us a lot of money. How much are you being paid?”

I asked for $1,500 …same as the Merlin farmer got.”

“Our costs are mounting up. How much do you think it will cost

to get a new gear made?”

“I would rather not think about that.”

Marjorie did not say it directly but she was likely thinking about that old

song…’Fools rush in where Angels fear tot red.’ Cool down, Alan, one

step at a time. Get your tools together.

“Let’s see…a set of open ended adjustable wrenches, a hammer…and most

important a spray can of nut loosening lubricant, a mechanics overalls…a peaked

cap to hide my eyes…a nice new red tool box…maybe an electric drill?

No, scrap the drill idea…too likely to do damage…also need a sports bag to bring

the gear home.”

“Alan, can you bring a bull gear across the border?”

“Not sure…one step at a time.”

Once again a dash of serendipity helped me on that score…more than a dash

of serendipity for that matter. That will come later.

It was late August when I flew to Detroit with my tool kid. Flew alone. No holiday. This

was business. Booked into a fancy hotel with an interior glass walled elevator as I remember.

No joy alone in an hotel. Made me feel sorry for sales executives. Lone hotel rooms

always remind me of the great John Candy movie titled Planes, Trains and Automobiles…a

lonely lost gregarious man ever on he move.

Early next day I put on my overalls and baseball cap. (Did promote the Detroit Tigers? Can’t remember),

grabbed my tool box and took a cab to the Food museum where my pass was waiting. Smooth at the

beginning until I stepped across the rope fence around the McCormick Reaper.

I set down the tool box and begin disassembling the reaper. Carefully. Soon a small crowd

was watching. Unusual to see a featured machine being taken apart. Like a watch repairman I

set the pieces in line. I was scared. What if I broke something. I soon got down to the

bull gear. Great brute of a gear. Quite stunning really. A piece of art. I managed to get

the shaft clear. All that I had to do next was slide the gear off the shaft.

Whoa! I pulled…twisted…tapped. Failed on all counts. The bull gear was rusted tight

to the shaft. By this time the crowd was bigger. “Keep calm, Al…no perspiration…act like

you know what you’re doing.”

“She’s trusted tight, folks. Old as the ages.”

Calm …Al…keep calm.

“Just a good shot of penetratng oil should help.”

And I gave both ends of the bull gear a good soaking.

“Give the stuff a moment or two to soak in, folks. And watch this.”

At which point, I grabbed the bull gear with both hands … twisted …the gear came loose.

Just for effect I spun the big gear and it whirled like a spinning dervish down the shaft

where I caught it, set it down,..and…And did I turn to the crowd and take a bow? I wanted

to do that but then carefully put the parts back on the reaper. Packed up my tool box after

giving the can of penetrating oil a kiss. No, I did not kiss the can. I wanted to kiss the can

but that would reveal too much about my state of nerves.

Before leaving the museum I dropped in on Peter Cousins to thank him and

then another wonderful thing happened.

“have you got anyone willing to make a casting for the new bull gear?”

I looked quickly at Peter. Was he setting me up? He was a serous kind of guy.

No light talk. No jokes.

“Not yet.”

“Here take this phone number. This fellow owns a factory outside Detroit. He might

be able to replicate the bull gear for you.”

So there was another big step in the project. As things turned out the factory owner

was quite willing to make me a new gear. No small task. I expected it would cost

a fortune.

“How much will that cost?”

“Nothing…do it as a favour for you guys on the other side of the border. “

“No, I will pay.”

“Nope, won’t let you…call it a neighbourly act … done for that old grouch Cyrus McCormick

who has been dead for years.”

A couple weeks later the new gear was made and somehow I managed to get the

gear from Detroit to Mississauga without a problem. Sam Markou, a good friend, was

in our truck when I brought the gear across the border. We were sent to a special

holding area where I explained the project to Canadian border guards. They cleared

the import. Not sure they cared much about it. This new bull gear was small potatoes in

the great scheme of things. A blip.

I worked all that fall improving the reaper. Some wood parts had to be refashioned. A whole

new reel windlass for instance. Easy work though even for a left handed historian.

Word got out to the local paper and a feature story was written. Friends came by often

Even our boys, then quite small, showed an interest. The McCormick reaper project was

a rock thrown in a small pool. The ripples spread out.

Then the fateful day arrived and I built two gigantic wooden crates for the reaper and the

separated cutters and wooden bed. All crated up and shipped air freight to the

Ulster National Folk Museum of Northern Ireland.

There it rests today. At least i think it is there. We have never heard a word about it.

I am not sure that anyone in Northern Ireland gives a sweet goddamn about the model

McCormick Reaper.

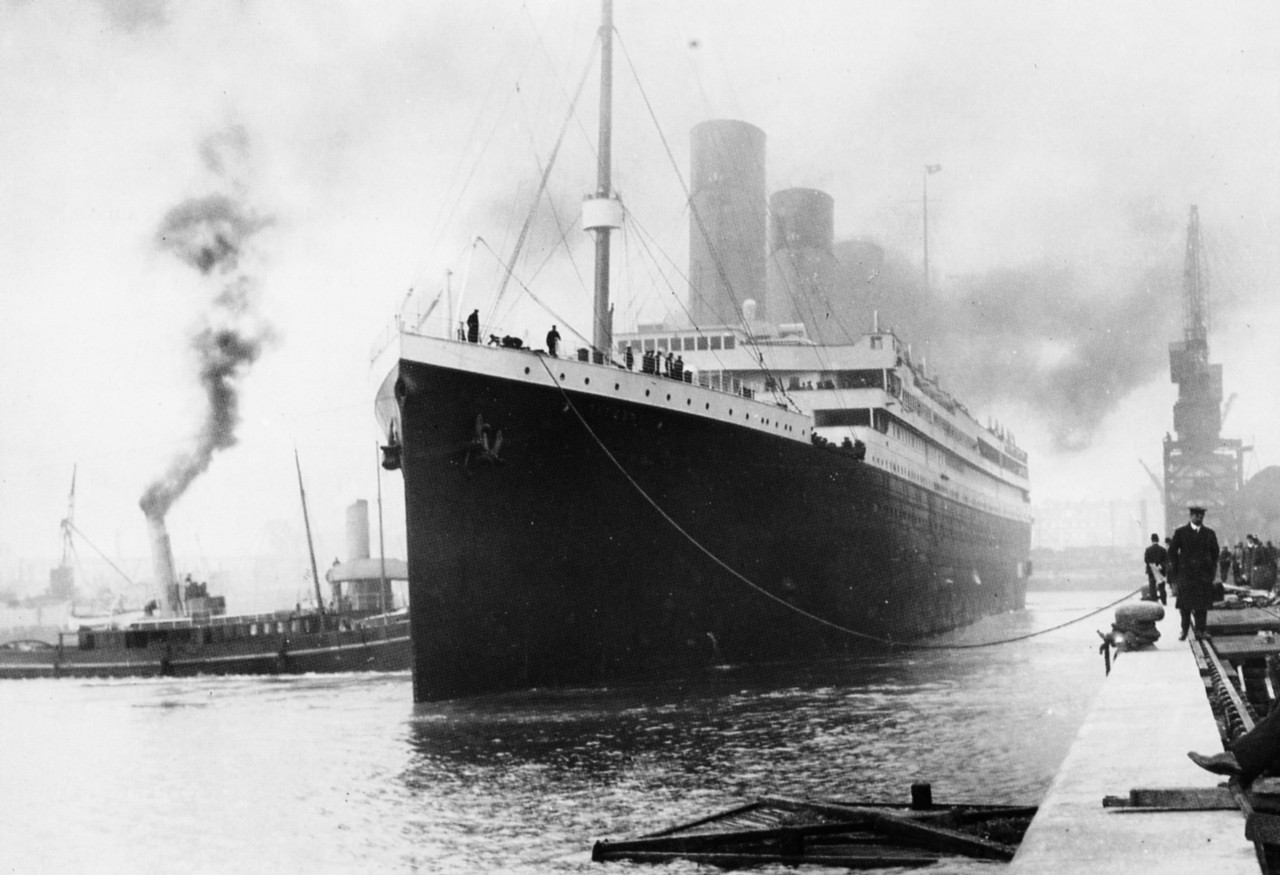

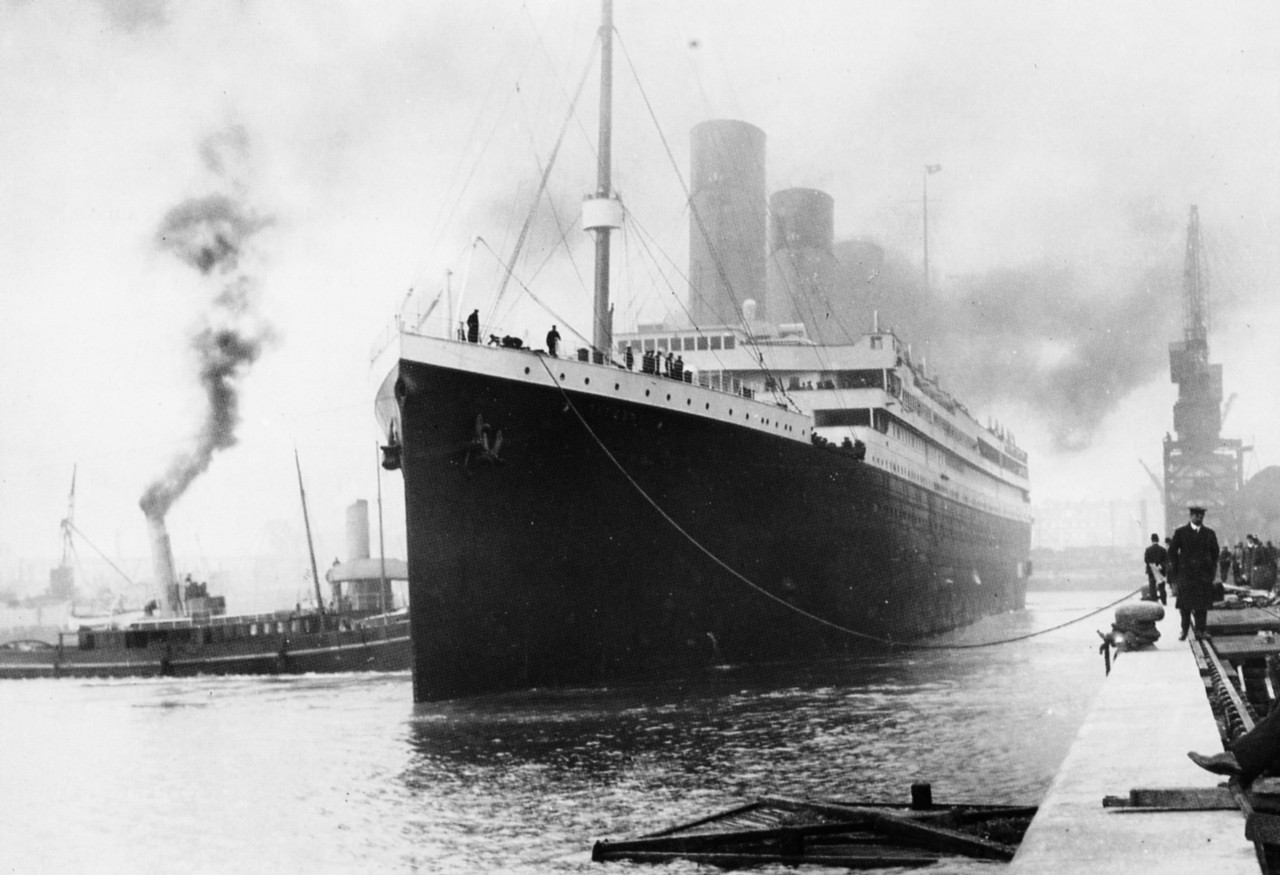

Bigger projects were done in Northern Ireland. Like the Titanic.

Your questions? “Did I make any money from the job?” I never really checked. Probably

lost a few dollars when everything is considered. If my dad had been alive at the

time he would have been impressed. How would I know? Because he would have

called me s goddamn fool which was his way of saying “I am proud of you”

alan skeoch

Nov. 2020

POST SCRIPT: THE ULSTER FOLK MUSEUM…NO SIGN OF THE MCCORMICK REAPER

NEXT STORY: WHO WAS CYRUS MCCORMICK?

POST SCRIPT BELOW: NO SIGN OF THE MCCORMICK REAPER IN NORTHERN IRELAND